Trending Today

Today we’re going to take a break from learning the game of Star Wars Legion to take a look at a very useful tool for the modern wargamer, 3D printing.

My personal experience with printing actually started with school. I’m an engineering student, and we basically have a 3D printing class. Don’t let this be daunting though. 3D printers are quite accessible to the newcomer and can be as easy or complicated as you want them to be.

My goal with this article is to take the experience I have using multiple printers and give you the tools to decide if you want to get a printer, what kind to get, and what to do with it.

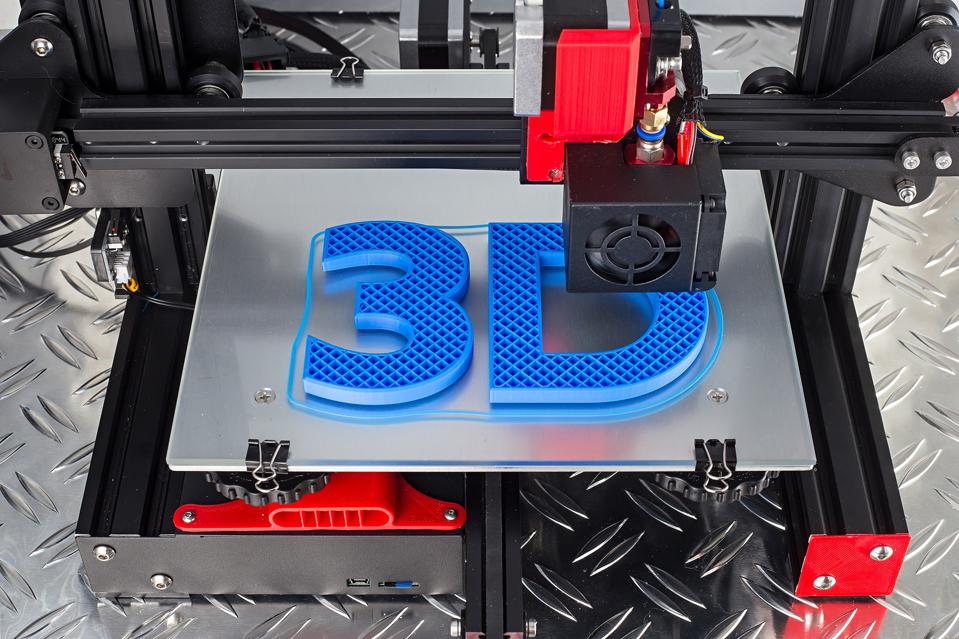

3D printing is a set of technologies that allow a machine to print a digital file in 3D space out of a variety of materials. The digital files that are generally used are called STLs which designate the shape and structure of an object in 3D space.

The two main types of 3D printers useful and accessible to wargamers are FDM printers and Resin printers. Between these two types of printers you are able to print small, highly detailed objects as well as giant pieces of terrain.

The way that the files needed for printing, STLs, are printed is by using Computer Aided Design (CAD.) CAD allows you to generate files yourself, edit files available online, or you can just find or buy premade STLs from a variety of websites.

FDM stands for fused deposition modeling. While what it stands for doesn’t really matter, it gives a clue to how these printers work. FDM printers are the ‘standard’ printer type, at least for the hobbyist. This type works by melting a material, usually plastic of some kind, while moving a nozzle in a path to trace the shape desired.

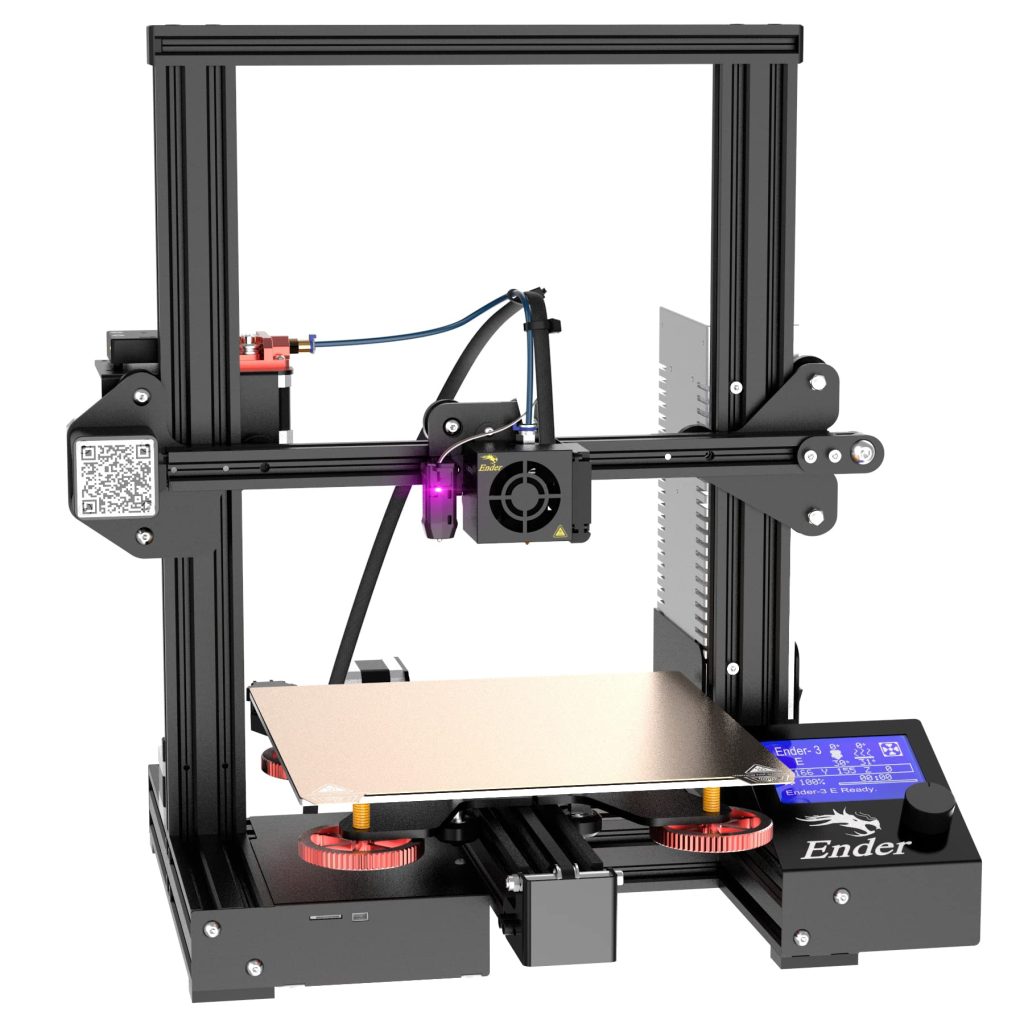

FDM printers are the ‘workhorses’ of the hobbyist. FDMs are usually the cheapest printers as well and can print quite large objects at the sacrifice of some fine detail. The FDM printer I have is an Ender model. Enders are a great starter printer as they are easy to assemble, quite hardy, easy to calibrate and highly moddable. These printers are often quite inexpensive as a big bonus.

FDM printers by their nature are usually the ideal tool for printing terrain pieces. This is because FDM printers can print large objects as well as having the cheapest available materials to print with to save costs on big print projects.

The biggest tip that can be given for FDM printers, as well as most printers, is to make sure your print surface is level. The easiest way to do this with FDM printers is place a sheet of paper under the nozzle and move it around the print bed making sure that the piece of paper is lightly squeezed at all points on the bed.

The main and most common type of filament used in FDM printers is Polylactic acid (PLA). PLA is actually made from renewable resources which is great. PLA has some of the best features for FDM printing which is why it’s commonly used. It has a low melting temperature and is fairly malleable. It does however not yield the strongest prints, so if you want more strength you’ll have to add more internal structure.

The other most common filament type is Acrylonitrile butadiene styrene (ABS). This type of filament is made from petrochemicals and has a higher melting point and yields generally tougher prints. ABS also requires you to have a heated bed whereas PLA does not.

Overall, you probably want to stick to standard PLA, at least for awhile, and branch into other materials at a later time if you have specific applications you want to use them for.

One thing to keep in mind about the various materials you use to print with an FDM printer is that you want to keep them sealed in their packages until you use them, and try to not let the filament sit out for a long time. Over time the filament has a tendency to absorb water from the air as well as get more brittle. These two things together can cause print failures. Basically if you aren’t going to be printing for awhile, put your filament rolls in sealed bags to keep them fresh.

The other main type of printer that is available to us is resin printers. Resin printers work by having a vat of liquid resin and then progressively curing the resin with UV light. Resin printers have much better detail than FDM printers but usually have much smaller print areas and more expensive material.

Resin printers are an excellent choice if your main goal with 3D printing is to print highly detailed models, usually miniatures for gaming. Resin prints are usually indistinguishable from normal injection molded models once painted.

Resin printers are still useful for terrain as well. Though the final products will be more expensive you are able to get incredible detail. One way to utilize resin printers when making terrain is to print what is often referred to as ‘greebles’. Basically these are parts that are hard to model by hand but can be printed easily. Taking a cardboard box, or other similarly shaped construction, painting it, and glueing on some printed elements like vents and doors can make great cheap terrain.

Resin Printers use, as the name suggests, resin as the material for prints. This resin is toxic and can be harmful. I myself use nitrile gloves while handling resin as well as have my printer located in a ventilated area. This isn’t official safety advice. Please look into safety procedures for handling resin to ensure safe handling.

National Institute for Occupational Safety and Health

MSDS sheet for a resin made by ELEGOO

In handling the finished prints you also need to clean the completed prints by running them through a solvent of some kind to remove any remaining liquid resin. I use Methyl Hydrate.

The other thing you need to do with resin prints once they are done being printed is to finish curing them. The printing process only cures the resin partially, so to complete the process you need to expose the prints to UV light. You may be wondering where you can find UV light; you can buy curing stations, or just UV lights. You also have access to a giant ball that generates UV light, the Sun. Sun curing is of course the cheapest option but not ideal as the Sun can often bleach prints and cure them unevenly.

Most resins are basically the same with minor differences and costs. However the biggest outlier is water soluble Resin. This resin as the name implies dissolves in water when uncured so you can forgo the harsh solvent chemicals and just use water instead. This is often preferable if you don’t have an area with great ventilation or you want to prevent more spills of harsh chemicals.

There are also clear resins which you can use for some great effects. You can even get hologram like effects with the right printing settings and 3D files.

When comparing the two main types of printers, we see some pros and cons of each style.

Likely the ideal scenario for any wargaming who wants to print a variety of models, would be to have both types of printers. One for big prints and one for detail. This is what I have.

However, probably when starting out you’ll be looking to only get one printer. The big choice really comes down to what you want to print. If you want to print big things such as terrain, go for an FDM printer. If you want to print small things like army miniatures, then go for a resin printer.

Computer Aided Design (CAD) is how we generate and edit 3D models, STLs, which we use to print. For the average hobbyist CAD is not required as there are many ways to get 3D files without generating them yourself. CAD is an incredibly useful tool that can be used to make anything you want, which is just part of the fun of owning a 3D printer.

The best free CAD software and the one that I use is Fusion 360. With access to a free license as long as you’re a hobbyist, you are able to model anything you want.

However if you are wanting something designed more for free flowing design then Blender is your go to. This software has tools that mimic real life sculpting so you can create intricate models.

STLs are the files that are used to generate the instructions to send to you printer. These files are generally great but can be a bit of a pain to edit precisely. It just takes some practice with your CAD software of choice to figure out the best way to edit in the way you want.

STLs are available all over the internet, both for free and for sale. Some great resources for free models include Thingiverse and Yeggi. Both sites have tons of 3D files and you just need to search for what you want.

If you are looking for more specialized and usually nicer 3D files then you probably will need to buy them. We have some files available in The Fifth Trooper store. Other sites include Imperial Terrain and Corvus Terrain. There are a ton of other sites that also have files so go explore and find models that you want to print. Remember to get files that are applicable to your 3D printers, if you only have a FDM printer, don’t expect to be able to get and print highly detailed minis.

Slicers are the final step between a STL and getting your printer working. Slicers take your 3D files and ‘slice’ them into flat sheets that a printer can print one layer at a time. The main slicer I use and one commonly used is Cura. There are a plethora of slicers to choose from, some 3D printers even come with their own slicers.

When setting up prints in slicing software there are a plethora of options to choose from that will affect how your printer functions. The best recommendation is to start with the manufacture settings when starting and then you can start experimenting from there.

For resin prints, you will have to put in supports to help make sure the print succeeds. A lot of purchased files will come ‘pre-supported’. Learning how to support prints properly is incredibly important. The basic tenet is that you can’t print on nothing. So whenever there is a shape that ‘sticks out’ you will have to support it. Usually the best way to learn to support models is by watching online tutorials as well as opening up pre-supported files in your slicer software and exploring how they’re supported.

3D printing is a great addition to the wargaming hobby. It gives you the ability to print amazing terrain and miniatures.

I really can’t recommend enough how much more 3D printing has added to my hobby. I have been able to create multiple tables of terrain for our local community to use, as well as unique miniatures that aren’t available to buy or unique sculpts to add to the diversity of your armies.

If you are looking for more information about 3D printing, the All3DP website is a great resource.

Copyright © 2024 The Fifth Trooper. All Rights Reserved.

3 Responses

So glad you linked to the ALL3DP website. It’s really a wealth of information.

Excellent article! Glad to see some 3D printing hobby aspects on here.

Just one smallish thing, ABS has some pretty harsh fumes and probably should only be used with ventilation.

For anyone else reading, it’s not too difficult, just have a box fan blowing out an open window and you should be fine.

PLA is really solid though, as is PETG. I typically use PETG as an ABS replacement when there may be thermal issues that PLA can’t handle.

Once again, great article Timbo, hope we see more like it!

Very timely article thank you… my resin printer arrived a couple of days ago and I’ve been tiptoeing around it… aim to actually run a print this weekend.